In a production plant, efficient material supply is essential to keep production running smoothly and cost-efficiently. Poor material supply and logistics can lead to unnecessary delays and downtime in production.

In this article, we'll give you some tips on how to optimize your material supply so that you deliver every customer order on time.

1. Planning of the material supply

Successful material provisioning starts with early planning of material requirements. To ensure smooth production, you should plan the material requirements for each production unit or operation in advance. In doing so, you should consider not only the quantity required, but also the exact time of material delivery.

At the same time, planning material supply includes the following three aspects:

- Material procurement: The procurement of the required materials should be planned well in advance to ensure that the materials are available on time. Here, it is important to establish a reliable supply chain and to consider alternative suppliers.

- Storage: Optimal storage of materials helps to speed up material supply and shorten lead times. Aspects such as the right choice of storage location, clear storage and quick accessibility of materials should be taken into account.

- Transport: The transport of materials should be planned effectively in order to avoid bottlenecks and to minimize the time required for material provision. Various means of transport such as forklifts, conveyors or automated transport systems can be used for this purpose.

2. Optimize inventory

There are several measures that can help optimize inventory management. Here are some possibilities:

- Analysis of stock: regular analysis of stock helps to identify overstocks and unused materials. These can then be reduced or removed from the warehouse in a targeted manner.

- Optimization of storage space utilization: efficient use of available storage space helps to minimize space requirements and reduce warehousing costs. For example, continuous racking systems or flexible workstation systems can be used.

- Use of technology: technological solutions such as barcode scanners, pick-to-light systems, pick-by-voice systems or automated storage systems can make warehousing much more efficient. They facilitate material provisioning and enable faster inventory control.

- Shortening delivery times: A shortened delivery time means that less material needs to be kept in stock. Close cooperation with suppliers and the use of just-in-time deliveries can help here.

3. Optimize material transport

The transport of materials within a company plays an important role in efficient and smooth production. Therefore, it makes sense to optimize material transport as well. Here are some tips on what to look out for in the process:

- Route optimization: The routes on which the material is transported should be as short and efficient as possible. Modern software solutions for route planning and optimization can help here.

- Transportation equipment: The choice of the appropriate means of transport is crucial for efficient material provision. Factors such as the type of material, the distance and the frequency of transport should be taken into account. Customized transport and picking trolleys from BeeWaTec offer the ideal solution here.

- Avoidance of empty runs: Empty runs should be avoided, as they cause unnecessary costs and are a waste of time. Careful planning and coordination of transports can help minimize empty runs.

- Automation: The use of automated transport systems such as conveyor technology or automated vehicles can make material transport more efficient and faster.

- Standardization: Standardizing material transport processes can help minimize errors and increase efficiency. Here, clear process flows should be defined that are adhered to by all employees.

4. Optimize workplaces

For optimal provision at the workplace, not only the transport there but also the workplace itself must be adapted. To optimize material provision, various lean solutions such as flow racks or conveyor lines can also be integrated directly at the workplace. In this way, all parts required for assembly or production are automatically provided. This creates a perfect symbiosis of storage and workstation systems for maximum productivity and ergonomics.

Another option is to design flexible workstation systems with shelving levels for open fronted storage bins, for example. Employees benefit from the elimination of individual walkways and are provided with ergonomic gripping paths.

5. Automate material supply

The automation of material supply processes can bring significant time and cost savings. Automated transport equipment such as automated guided vehicles (AGVs) or automated roller conveyors / conveyor belts can speed up material handling and minimize errors. These systems can also reduce the burden on personnel and improve safety.

But digital systems can help not only with transportation, but also with managing and recording inventory. Here, for example, information about inventory from production is collected using sensors and monitored in real time. Process chains are thus set in motion automatically and necessary information is shared immediately.

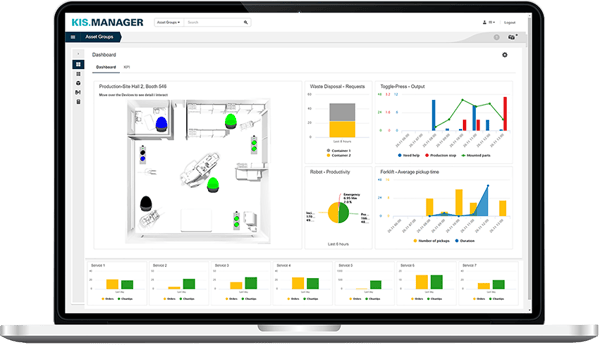

KIS.ME products offer precisely these advantages of process monitoring and control in the cloud. With the help of sensor data, pushbutton boxes and signal lights, you create transparency and gain access regarding the status of your transport orders or waste.

Discover products from KIS.ME >

Conclusion - How to optimize your material supply in production

Efficient material provisioning is essential to ensure smooth production. With the tips mentioned above, you can optimize your material provisioning processes and save time and costs. Taking the above-mentioned components into account, you will reduce unnecessary transport routes and ensure an ideal material flow. It is also important that you regularly review the processes and optimize them if necessary in order to achieve continuous improvement.

How BeeWaTec provides support:

With the help of individual flow racks, conveyor sections, transport carts, workstation systems and automation solutions, you can design lean processes and remain flexible for the future. Increasing variant diversity requires flexible concepts in design. Contact us and together we will design your operating equipment for lean and sustainable production.

Find or design your material flow systems

With our modular system you can build whatever lean solution you need.

Discover your possibilities, exisiting solutions or build your own material flow system with BEEVisio in 3D.

_Web_01_01.jpg?width=1240&name=Beewatec-3-(37)_Web_01_01.jpg)