Kaizen - Kaizen principle, Kaizen methods & importance for companies

In a world where markets are changing rapidly and competition is more intense than ever, organizations are looking for effective methods to remain...

Modular pipe systems

Attachments

7 min read

![]() Rainer Buckenmaier

:

17.April.2023

Rainer Buckenmaier

:

17.April.2023

Ergonomics is more and more included in the language use of many companies as it deals with the performance, health and safety of employees. Many work activities and work environments are nowadays studied and optimised under ergonomic criteria, with the aim of reducing health hazards and at the same time increasing performance.

In this article, we give a general overview of the topic of ergonomics in an industrial context, answer theoretical questions and take a look at practical implementation. You will learn what constitutes ergonomic work design and how you can design ergonomic working conditions for your employees.

The word ergonomics is composed of the Greek words "ergon" (for "work") and "nomos" (for "law") and describes the science of human work. The science of work aims to design a workstation in such a way that people can work optimally.

Optimal work means:

As in the field of occupational health and safety, the prevention of damage caused by heavy, incorrect or excessively stressful work has top priority. The goal is the optimal adaptation of working conditions to people and a human-centred design of work (see also Human-centred design according to DIN EN ISO 9241-210).

In short: ergonomics supports working people in completing a work task.

The laws of ergonomics also play a decisive role in the design of machines and man-machine interfaces (= interactions between technology and people).

In order to achieve the above-mentioned goals, workplace design is divided into two sub-areas:

Physical ergonomics is what most people probably understand by the term ergonomics. The design of equipment and the design of the working environment.

This includes criteria such as:

The body movements (e.g. turning or bending) and activities (e.g. lifting or pushing) themselves, which a worker performs, for example, are also part of physical or physiological ergonomics. These play an important role in the calculation of ergonomic key figures and are part of anthropometry (= science of body measurements), where safety measures such as minimum distances or maximum opening widths are defined.

To be able to assess whether an activity is ergonomic, the following aspects are important:

Psychological factors can also have a major impact on the health of employees as well as on the quality of work.

These include aspects such as:

Monotonous work, for example, has a negative effect on attention and perception. The susceptibility to errors increases and employees tire more quickly, which makes them dissatisfied in the long run.

Multitasking and high (physical or mental) demands, on the other hand, increase the stress level. When there is a lot of stress or prolonged stress, motivation decreases and so does performance. In addition, the risk of (long-term) damage to health increases (e.g. burnout).

What many people forget, however, is the fact that people need a certain level of activation in order to be able to perform. According to the Yerkes-Dodson Law, both underchallenge (e.g. through monotony) and overchallenge (e.g. through stress) are equally bad for productivity. Therefore, it is recommended to strive for an ideal balance."

The perception of mental stress is subjective and thus differs from person to person.Keep this in mind if you work in work preparation or process optimisation, for example, and design workstation systems or work processes. Consider changing activities (= job rotation), a (re)division of work steps or further relief in order to maintain the motivation and health of your colleagues.

_web.jpg?width=600&height=400&name=Beewatec-3-(54)_web.jpg)

Ergonomics has three core objectives:

Through preventive occupational safety and the ergonomic design of workstations, work environments and activities, the above-mentioned goals can be achieved. More efficient processes, a reduction in occupational illnesses and many other benefits are the result"

In summary: Performance, health and safety on the one hand (= pro) contrast with costs and time expenditure on the other (= con).

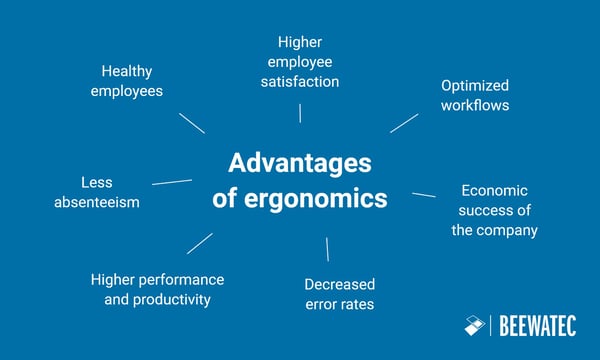

Ergonomic measures provide support in all areas of daily life. In industry, both employers and employees benefit from a variety of positive effects:

A workstation is considered ergonomic if it has been assessed and designed in accordance with the principles of occupational health and safety, taking into account both physical and mental aspects.

The assessment and design of the work includes:

The REFA management system (REFA - Verband für Arbeitsgestaltung, Betriebsorganisation und Unternehmensentwicklung e. V.) is a systematic approach to assessing and improving ergonomics in any workplace. It helps identify risk factors related to awkward postures, repetitive movements and heavy lifting, which can then be eliminated through appropriate measures.

The end result is an ergonomic workplace that not only reduces the risk of injury, but also improves employee satisfaction, productivity and the overall quality of working life.

Basically, the measurement of ergonomics can be done by assessing these four criteria.

Safety measures include the assessment of physical conditions, such as the layout of the workplace, the placement of work equipment and the design of tasks.

Efficiency measures assess how quickly tasks are completed and how much energy is consumed during a task.

Comfort measures assess the posture of employees during a task and the physical strain.

Finally, performance measurement assesses how well employees are able to perform their tasks with minimal errors.

To get an accurate assessment of workplace ergonomics, it is best to collect data from a variety of sources, such as job analysis surveys, biomechanical assessments and usability tests. This data can then be analysed to identify possible ergonomic improvements that can be implemented for greater efficiency and satisfaction for all employees"

Before you spend a lot of time and money on complex analyses, we recommend that you draw on your experience with existing workstations and thus conduct a simple survey of your colleagues.

Our experience shows that they will be able to give you comprehensible and practice-oriented optimisation potentials right off the bat. They know exactly which postures are uncomfortable, which work steps represent an unnecessary workaround, or which SLC containers are too heavy.

An open exchange is essential, because in the end you design the workplaces for exactly these people.

Involving the employees in the design of new workplaces can already eliminate a large part of the problems (e.g.: unfavourable sitting posture, back problems, high error rate, etc.). At the same time, you sensitise everyone in your company by addressing ergonomic issues.

We have prepared a checklist with questions for your colleagues for this purpose.

Especially in industry, the topic of ergonomics plays a central role, as many, often physical activities or work processes are repeated over long periods of time (many hours a day, over weeks, months and years).

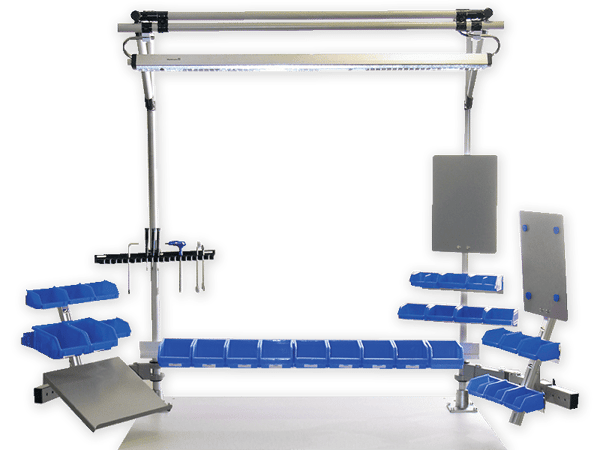

Using principles of lean production and lean solutions from BeeWaTec, ergonomics in the workplace can be increased easily and cost-effectively. Our modular system of tube plug-in systems, lift sets, lights and many other accessories form the optimal basis for this.

You can find a detailed description with many more examples of our tips in our article "8 tips for ergonomic workplace design in industry".

What unites all BeeWaTec products is flexibility. With a finely tuned modular system for lean production, we bring everything you need to design ergonomic workstations and implement your ergonomic requirements.

Your personal BeeWaTec contact will be happy to advise you on our products for more ergonomics.

Ergonomics is an important adjusting screw for more health, safety and performance at the workstation (see also Occupational Health and Safety Act). Ergonomics is not only concerned with physical aspects but also with people's psyche, as this also has an influence on the quality of work.

A mix of methods can be used to record and evaluate ergonomics at the workplace. The REFA management system offers a systematic guideline for this. As a further aid, you can start quickly and easily with a survey of your colleagues and identify many potentials for optimisation.

There are 8 important tips to consider when redesigning operating equipment (e.g.: feeding material and information). With the BeeWaTec construction kit you have the ideal prerequisite for the ergonomic design of workplaces and the implementation of your ergonomic requirements.

As one of the leading providers of lean equipment construction and lean production, we support you with flexible hardware and know-how. Discover the possibilities of our modular system and benefit sustainably from more ergonomics and flexibility.

In our showroom you will find many clever solutions and successful projects. Take advantage of our experience for your workstation design. We will be happy to support you.

In a world where markets are changing rapidly and competition is more intense than ever, organizations are looking for effective methods to remain...

At a time when companies are striving to increase efficiency and cut costs, the concept of lean management has established itself as a highly...

The material flow is an important part of every production and logistics. It describes the physical movement of materials, products and goods through...