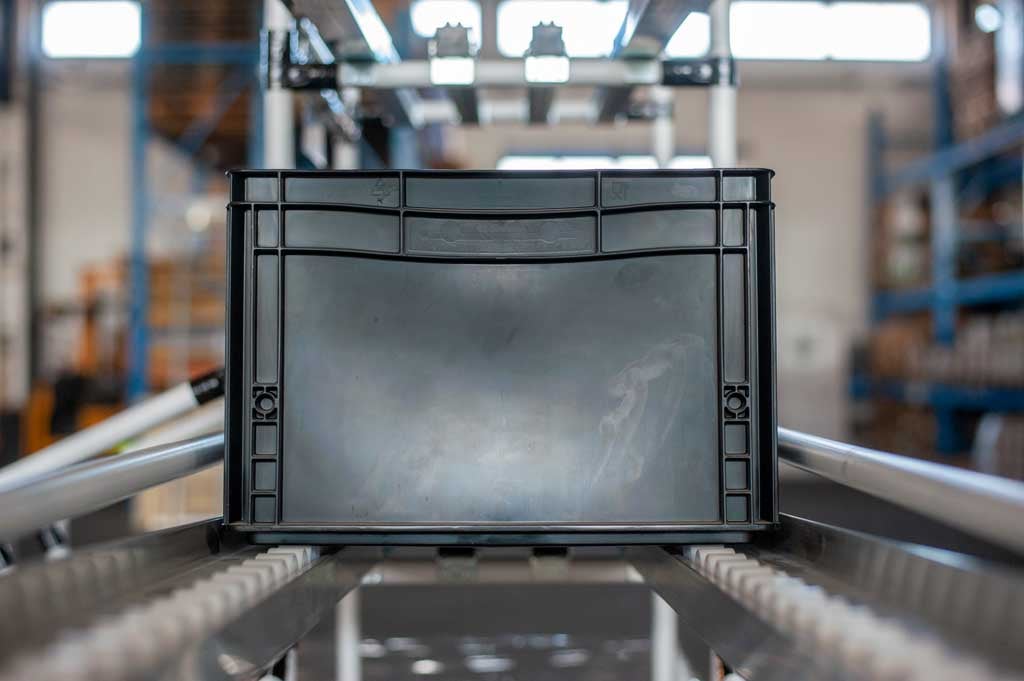

Automatic movement of carriers by gravity

Load carriers are moved from the filling side to the removal side by means of a gradient. In this way, load carriers / transport containers can automatically move up and ensure a reliable delivery.

Modular pipe systems

Attachments

Roller tracks enable the movement of SLC boxes, cartons, containers or individual parts from one point to another with the help of gravity. Two roller tracks form a roller conveyor (without drive), which keeps the load carrier on track with the help of lateral guides.

Roller conveyors are an indispensable component in many pipe constructions to get a fast delivery of boxes and to ensure the FIFO principle. From a simple continuous flow system for load carriers / transport containers / cartons with a straight track, to curved and all-side rollers, to a crate changing system, roller tracks are the ideal solution for implementing efficient conveyor technology in your company.

Load carriers are moved from the filling side to the removal side by means of a gradient. In this way, load carriers / transport containers can automatically move up and ensure a reliable delivery.

Roller tracks can help workers to move heavy workpieces (>20 kg) simply by guiding them manually, e.g. between two workplaces.

Roller tracks are also used for an easy delivery of containers or workpieces over longer distances. Here, the movement is usually not realised by a gradient, but by the supply of external energy from , for example, driven systems (conveyor belts).

Our roller tracks come in numerous designs and with different roller diameters and can be combined with all of our systems (steel pipe racking system, aluminium pipe racking system, steel square system and aluminium square system). They can be easily adjusted in length (standard length is 4000 mm for GP and 3000 mm for UR roller tracks).

The roller tracks from our manufacturer G.S. ACE have excellent running properties, smooth, low-noise passage of parts even at low gradients, and high impact resistance. Their high stability ensures a long service life. They are available in numerous designs for different requirements.

Various accessories, such as special fastening elements, lateral guides and stoppers, round off the portfolio and offer an optimal connection to the pipe racking system.

Our GP roller tracks have rollers that run in one direction. These are mostly used in flow racks and straight conveyor lines.

Versions:

Materials:

Also available in conductive version (ESD).

Our UR roller tracks are roller tracks with rollers that run in several directions. These are used for corner solutions or for moving the load carrier, e.g. to a subsequent workplace.

Versions:

Materials:

Also available in conductive version (ESD).

We recommend to use roller tracks with integrated lateral guides (= collar on each roller). This not only saves you money, but especially space, as no additional lateral guide is required.

Slide pipes form an inexpensive alternative to roller tracks. These are special pipes, with a smooth sliding surface, on which e.g. SLC boxes can be moved over short distances and also with the help of gravity.

Depending on the combination of roller track and load carrier, noise can be generated when moving, for example, KLT containers.

For special requirements in terms of low noise, we offer roller tracks with rollers made of rubber or with a special body made of plastic.

Contact us if you have any questions, want to learn more or start your project.

Fill out this form or contact your personal sales representative in your region

directly.