6 min read

Material flow in production and logistics - Definition & all you need to know

![]() Karsten Weiß

:

04.Juli.2023

Karsten Weiß

:

04.Juli.2023

The material flow is an important part of every production and logistics. It describes the physical movement of materials, products and goods through the entire manufacturing process. Efficient material flow design can help avoid bottlenecks and delays, increase productivity and reduce costs.

In this article, you will learn what constitutes a lean material flow, how to optimize it and which factors you should take into account

Content

- What is the material flow? (Definition)

- Analysis of the material flow - optimization in 5 steps

- Challenges in designing the optimal material flow

- Choosing the right transport and storage equipment

- Material flow systems from BeeWaTec

- Conclusion

1. What is the material flow? (Definition)

The material flow describes the path taken by materials or products from procurement to sales within or between companies. It includes all processes and stations through which the material or product passes, such as production, storage, picking and distribution.

In contrast to classic "logistics", which is primarily concerned with the planning and control of materials and information, material flow focuses on technical and organizational implementation.

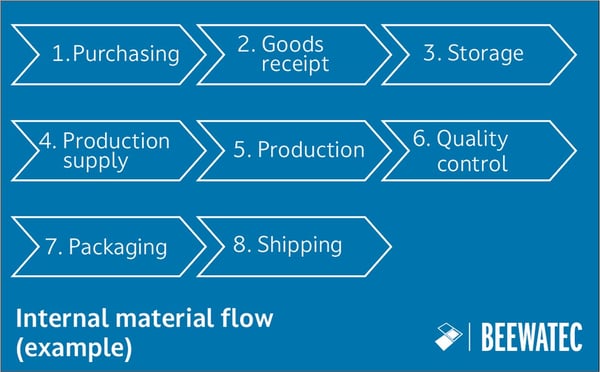

There are two types of material flow: in-plant material flow and interplant material flow.

1.1 Internal material flow

Intra-company material flow describes the transport of goods within a company, for example between production sites or from production to the warehouse. The aim here is to optimize logistics processes within the company, reduce waste and improve the utilization of production facilities and warehouses.

When it comes to internal material flow, there are various factors that need to be taken into account to ensure efficient and smooth execution. These include:

- Planning: Careful planning of the material flow is important to avoid bottlenecks and waiting times. Here, the processes from procurement to production to shipping should be planned and optimized in detail.

- Organization: Efficient organization of the internal material flow is essential. This includes, among other things, clear warehousing, clear responsibilities and workflows, as well as a functioning IT system for controlling and monitoring the flow of materials.

- Automation: Automation technologies such as conveyor technology, automatic storage systems or transport robots can accelerate the material flow and reduce errors.

- Education and training: Employees must be appropriately educated and trained for the smooth execution of the material flow. In particular, the aspects of occupational safety, ergonomics and quality assurance should be taken into account.

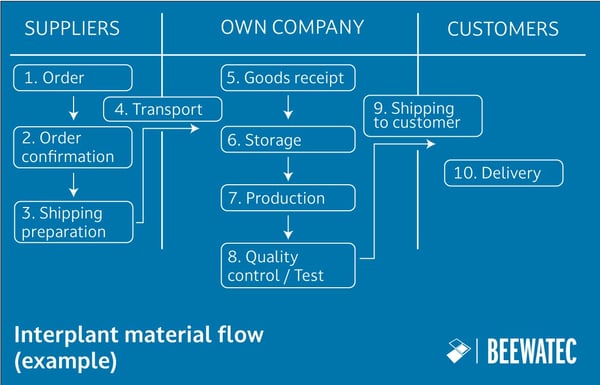

1.2 Interplant material flow

In contrast, inter-company material flow involves the transport of goods between different companies, for example from supplier to customer. The main aim here is to optimize the supply chain between companies and ensure a smooth supply.

In this context, there are various aspects that need to be taken into account in order to ensure efficient handling of the material flow. These include:

- Coordination: Good cooperation between the companies and suppliers involved is important in order to be able to handle the material flow smoothly. Clear agreements and communication channels should be established to avoid bottlenecks and delays.

- Standardization: Standardization of processes and interfaces can help to simplify and accelerate the material flow. For example, uniform data formats and labels for goods should be used.

- Monitoring: Continuous monitoring of the material flow is important in order to detect possible disruptions or delays at an early stage and to take countermeasures.

- Sustainability: Aspects of sustainability should also be taken into account in the interplant material flow. These include, for example, the avoidance of unnecessary transport and the use of environmentally friendly means of transport.

2. Analysis of the material flow - optimization in 5 steps

The material flow analysis is a valuable tool to optimize the material flow in a company. The aim of the method is to visualize the material flow as a whole and thus to uncover weak points in the material flow. There are different approaches, but in general the material flow analysis includes the following steps:

Step 1: Recording the actual state

Here, all relevant data and information about the current material flow are recorded, such as production processes, locations, stock levels and transport routes.

Step 2: Visualization of the material flow

Based on the collected data, the material flow is displayed graphically to get an overview of the current state. Bottlenecks, inefficient processes or other problems can be identified.

Step 3: Evaluation and analysis

The material flow is critically examined to identify weaknesses and potential for improvement. Here, for example, key figures such as throughput times or waiting times are determined and analyzed.

Step 4: Development of optimization opportunities

Based on the analysis, improvement options are developed to make the material flow more efficient (= material flow planning). Here, for example, the redesign of production processes, the optimization of inventories or the modification of transport routes can be considered.

Step 5: Implementation and monitoring

The developed improvement measures are implemented and the material flow is regularly monitored and adjusted if necessary. In this way, a sustainable and effective optimization of the material flow can be achieved.

3. Challenges in the design of the ideal material flow

The design of material flow in production and logistics often presents companies with major challenges. A central challenge is to ensure an efficient and cost-effective material flow that also meets the requirements of quality and sustainability. Various factors must be taken into account here, such as the spatial conditions, the available technology, the number of products and the transport volume.

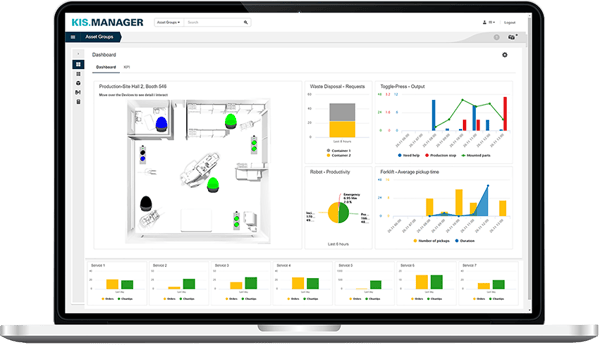

Another challenge is to monitor and optimize the material flow in real time. This requires the use of suitable IT systems and sensor technologies to continuously measure and control the material flow. The integration of autonomous systems such as robots or driverless transport systems can also play an important role here.

In addition to these technical challenges, human factors are also of great importance. Smooth cooperation between the various departments and employees is essential to make the material flow efficient. Employee qualifications and training in the use of the technologies employed are also important factors that must be taken into account.

Companies that successfully master these challenges can benefit from lean processes and higher productivity.

4. Selection of the correct transportation and storage equipment

Choosing the right means of transport and storage is an important factor in designing the flow of materials in production and logistics. Various aspects must be taken into account, such as the nature of the material, the distance between the individual stations and the transport time. Environmental compatibility and costs also play a decisive role.

Industrial trucks such as forklifts, pallet trucks or stacker cranes are generally used for the internal flow of materials. When selecting suitable equipment, care must be taken to ensure that it has the required load-bearing capacity and maneuverability while enabling efficient and safe operation.

Various means of transport such as trucks, trains or ships are available for interplant material flow. Here, various aspects such as transport costs, delivery time and infrastructure availability must be taken into account. The choice of the right packaging is also of great importance to ensure safe and efficient transport handling.

The choice of the right storage system is also an important factor in the design of the material flow. Various criteria such as storage capacity, turnover frequency and spatial conditions must be taken into account. Depending on the requirements, different systems such as rack storage, block storage or flow racks are used.

Overall, the selection of the right means of transport and storage is a complex process that requires comprehensive planning and coordination.

5. Material handling systems from BeeWaTec

One of BeeWaTec's most important approaches is the implementation of lean principles in our customers' material flow processes. Here, the material flow is optimized in a targeted manner to minimize waste and create a lean, efficient process.

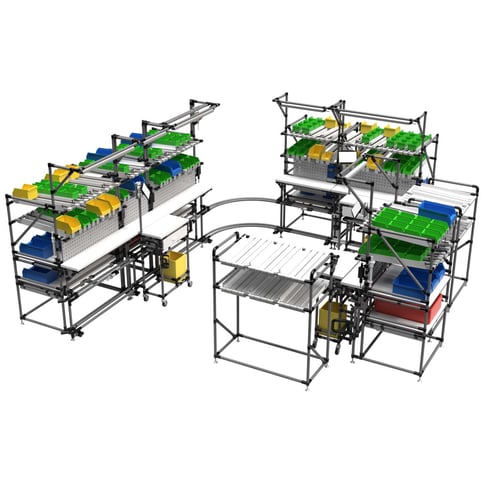

An important aspect of optimizing material flow is selecting the right means of transport and storage. Through a lean modular system of pipe-racking systems, we offer our customers the optimal basis for designing individual workstation, shelving, transport and material flow systems.

5.1 Conveyor lines

By integrating conveyor lines / roller conveyors, materials and products can be transported quickly and efficiently from one workstation to the next without the need for manual intervention by employees. The movement of the load carriers or materials can be realized either by means of gravity (inclined roller conveyors) or with the help of driven systems. Conveyor lines can be implemented quickly, easily and cost-effectively and ensure the FIFO principle during storage and assembly.

5.2 Flow racks

Flow racks also ensure a lean material flow by moving the material automatically (by means of gravity). They ensure that there are no pauses or gaps in the staging process and that the material can always be removed easily and quickly from the same place. A flow rack has a compact design and supports efficient and lean layout planning within production.

5.3 Carts and Trolleys

Material and transport trolleys (also: picking trolleys) are one of the most important components for the provision of material within production. Through them, materials, semi-finished products or ready-packed products can be quickly and safely stored temporarily and unloaded at the appropriate place.

Additional principles such as Kanban or Milkrun help to ensure a demand-oriented provision of goods and materials. In this way, there is no stagnation within the assembly or production process.

More about carts and trolleys >

5.4 Workstation systems & assembly lines

Material flows also take place within a workstation system or assembly line, which should be well thought out, i.e. follow the (assembly) processes. By designing workstations and assembly lines in a sensible way, unnecessary movements and transports can be avoided. Employees can concentrate on assembly without having to travel long distances to get materials and tools. At the same time, flexibly designed workstation systems from BeeWaTec offer the possibility of designing them in such a way that they can be easily and quickly adapted to current production needs at any time.

More about workstation systems >

5.5 Autonomous mobile robots

Autonomous mobile robots (AMR) can move autonomously through the production floor or warehouse, transporting goods from one place to another without the need for human intervention. They can automatically communicate with other equipment such as machines or conveyor systems to ensure a smooth flow of materials. The use of autonomous mobile robots can also reduce bottlenecks in material flow, as the robots can respond quickly and flexibly to changes in production. In addition, they can help optimize inventories by automatically monitoring and replenishing stocks.

More about autonomous mobile robots >

6. Conclusion

An efficient material flow is an important success factor for companies in production and logistics. Optimizing the material flow can lead to an increase in efficiency, a reduction in costs and an improvement in delivery performance. Various factors must be taken into account, such as the design of the layout, the choice of means of transport and storage, and the analysis and monitoring of the material flow. Companies that continuously optimize their material flow processes and can react flexibly to changing market requirements have a competitive advantage over their rivals. It is therefore worth investing in the analysis, design and optimization of the material flow in order to be successful in the long term.

Find or design your material flow systems

With our modular system you can build whatever lean solution you need.

Discover your possibilities, exisiting solutions or build your own material flow system with BEEVisio in 3D.

_Web_01_01.jpg?width=1240&name=Beewatec-3-(37)_Web_01_01.jpg)