5 min read

ESD (Electrostatic Discharge) - Meaning & Protection for the Industry

![]() Rainer Buckenmaier

:

27.Juli.2023

Rainer Buckenmaier

:

27.Juli.2023

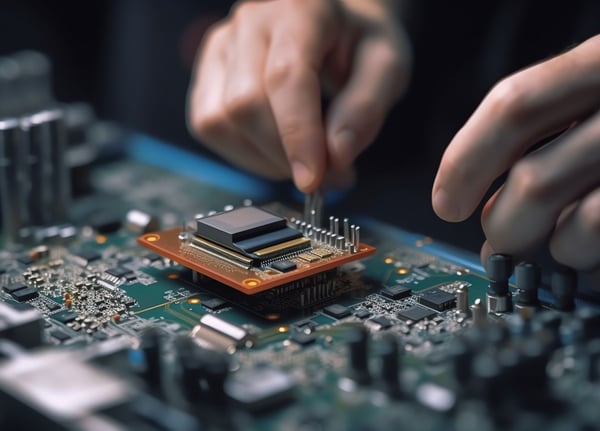

Electronic devices have become an indispensable part of our daily lives. From smartphones and laptops to industrial automation technology, they all play a significant role in our modern world. However, while we enjoy the numerous benefits of these technologies, there is an invisible threat that can jeopardize them: Electrostatic Discharge (ESD).

In this blog article, we will dive deeper into what ESD means, how it occurs, and the risks associated with it. Additionally, we will provide tips for ESD protection and shed light on the importance of ESD testing and certification

Content

- What does ESD mean?

- How does ESD occur?

- Dangers of ESD

- ESD protection measures

- Do I need ESD facilities and equipment or not?

- Designing an ESD workplace

- ESD testing and ESD certification

- Tips on dealing with ESD

- Conclusion

1. What does ESD (Electrostatic Discharge) mean?

ESD (Electrostatic Discharge) refers to the sudden transfer of electric charge between two objects with different electrical potentials. This discharge can cause serious damage to electronic components and devices. As electronic devices become smaller and more sensitive, they are increasingly vulnerable to ESD. Even a small discharge can be enough to damage microchips and impair the functionality of a device.

Difference between ESD and ELF

ELF stands for "electrically conductive" and is an internal BeeWaTec designation that ensures electrical conductivity, meaning an electrical resistance of < 10^9 ohms, for components and structures. Customers must verify if this meets their requirements. The basis for designing a system to protect electronic components and assemblies is the standard according to DIN EN 61340-5-1.

Note: When designing your equipment, ensure that components such as rollers, rails, joints, etc., have the necessary conductivity. For this purpose, we offer various options and materials (e.g., galvanized joints, ELF rollers, or ELF plates).

All conductive products are marked with the ESD symbol in our new Lean catalog.

![]()

ESD symbol for marking electrically conductive components

2. How does ESD occur?

ESD can occur in various ways. The most common cause is the friction between materials. When two materials (e.g., plastics) rub against each other or are separated, electrons can be transferred, generating an electrostatic charge. This charge remains on the surface of the materials or can be transferred to other objects when they come into contact. Electromagnetic fields or electrical discharges can also trigger ESD events.

3. Dangers of ESD - Electrostatic Charging and Sudden Discharges

ESD can cause significant damage to electronic devices. Microchips and other sensitive components can be damaged or destroyed by an ESD discharge. This leads to costly repairs or complete device failure.

The impact of ESD can also be latent, meaning that a device may be damaged by an ESD discharge but fail only after some time has passed. This can result in malfunctions, data loss, or even safety risks. It is essential to take ESD protection seriously and implement appropriate measures to safeguard electronic equipment and ensure the reliability of electronic systems.

4. ESD protection measures - Protection against charges.

To protect against ESD, you should take the following measures, if necessary:

- Wear ESD protective clothing, such as conductive shoes, wrist straps, and garments.

- Design electrically conductive equipment / Lean solutions.

- Use antistatic mats and conductive packaging.

- Ensure that you and your work environment are grounded to dissipate static charges.

- Avoid friction and electrostatic charging by handling materials carefully and minimizing direct contact with sensitive electronics.

- Use ESD protective devices, such as ionizing air cleaners, to reduce static charges.

ESD-wristband

5. Do you need ESD facilities and equipment or not?

Whether you need ESD protection depends on your activities and environment. If you work regularly with electronic components or operate in an environment with electrostatic risks, ESD protection is essential.

Even if you are not directly involved with electronics, static discharges through clothing or other objects can still cause damage to electronic devices. It is therefore crucial to recognize the potential hazards of ESD and take appropriate protective measures.

6. Designing an ESD workstation area

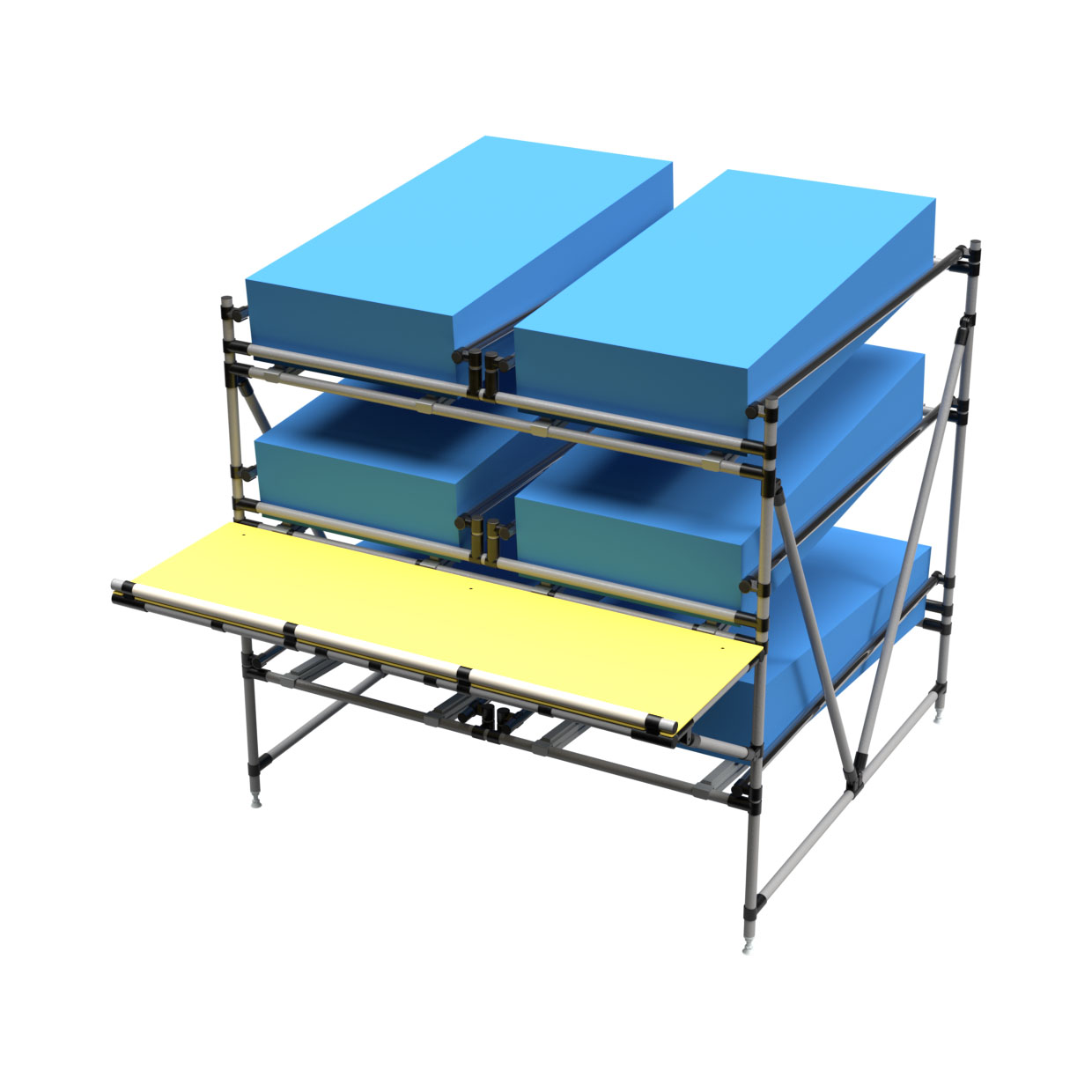

An ESD workstation is a specially designated area (ESD protected area or EPA, also known as "electrostatic protected area") that provides ESD protection by preventing electrostatic charging. It includes antistatic work mats, conductive flooring, grounding connections, and other measures to control electrostatic charges. ESD workstations are particularly important in the electronics industry, as well as in other fields where sensitive electronic components are handled. A well-designed ESD workstation minimizes the risk of ESD events and protects electronic devices.

Note: When designing your equipment, ensure that components such as rollers, rails, joints, etc., have the necessary conductivity. For this purpose, we offer various options and materials (e.g., galvanized joints, ELF rollers, or ELF plates).

All conductive products are marked with the ESD symbol in our new Lean catalog.

An ESD rack unit made from BeeWaTec's pipe racking system, with galvanized joints, ESD plates, and steel pipes coated with a certain amount of graphite for conductivity.

Do all attachments need to be electrically conductive?

Not necessarily all attachments in an ESD workstation need to be electrically conductive. The requirements for ESD workstations depend on the specific needs and risks of the work environment. However, some attachments indeed need to be conductive to minimize the risk of electrostatic discharges and protect electronic components from ESD damage.

Here are some examples of attachments where it is recommended that they are electrically conductive:

- Work Surface: The work surface, where sensitive components are processed, should be conductive to dissipate electrostatic charges from the hands of employees and reduce the possibility of ESD events (ensure grounding through an appropriate flooring material).

- Frame: The frame of a workstation should be conductive to establish a clean, conductive connection between the work surface and the floor.

- Casters/Feet: These elements should also allow ESD events to be dissipated through the floor, making an ESD-compliant floor essential.

- Conductive Containers: Storage or holding containers for electronic components should ideally be conductive to prevent electrostatic charging and minimize the risk of ESD.

- Conductive Tools: In some ESD-critical areas, specialized tools that prevent electrostatic charging may also be necessary.

For other attachments such as bottle holders, monitor mounts, or clipboards, electrical conductivity may not be strictly necessary. It depends on the specific situation whether these parts need to be coated or treated with ESD-safe materials.

In general, all attachments in an ESD workstation should be designed to minimize the possibility of electrostatic discharge. This means that electrically conductive components are recommended when it comes to protecting sensitive electronics, while other non-conductive attachments may be permissible as long as they meet ESD guidelines and requirements.

7. ESD testing and ESD certification

ESD testing is essential to ensure the effectiveness of protective measures. This includes inspecting ESD workstations and providing training to employees on ESD protection procedures. ESD certification confirms that a workstation meets the required standards for ESD protection, contributing to the quality and reliability of electronic devices.

BeeWaTec conducts testing and ESD measurements according to DIN EN 61340-5-1 during in-house assembly and provides the measurement protocol upon request.

8. Tips for ESD protection

- Educate yourself and your employees about ESD and its impact to raise awareness of the dangers.

- Regularly train employees on ESD protection measures and ensure they wear appropriate protective clothing.

- Set up ESD workstations according to the requirements and maintain them in good condition.

- Periodically test the effectiveness of ESD protection measures through ESD testing.

- Keep ESD-critical areas clean and free from static materials

9. Conclusion

ESD poses a real threat to electronic devices, but with appropriate protection measures, we can minimize this risk. ESD protection is essential in environments where electronic components are handled.

By designing an ESD workstation, implementing protective measures, conducting regular testing, and providing training, you can extend the lifespan of your devices, reduce downtime, and avoid costly repairs. Stay up-to-date with ESD protection practices and consistently implement them to safeguard your electronic devices and maintain their performance.

Do you need ESD-capable racks and equipment?

BeeWaTec offers a wide range of individual components for designing custom and electrically conductive (ELF) equipment. Contact us for more information.

_Web_01_01.jpg?width=1240&name=Beewatec-3-(37)_Web_01_01.jpg)