Kaizen - Kaizen principle, Kaizen methods & importance for companies

In a world where markets are changing rapidly and competition is more intense than ever, organizations are looking for effective methods to remain...

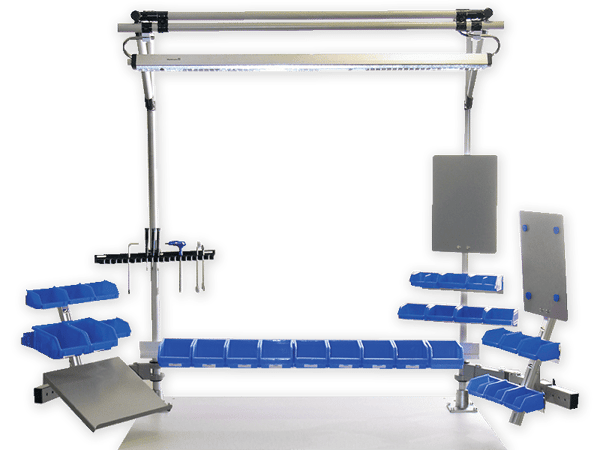

Modular pipe systems

Attachments

Ergonomic workstation design promotes safety, health and performance (= goals of ergonomics) at the workstation and is part of the Workplace Ordinance and the Occupational Health and Safety Act.

Especially in industry, the topic of ergonomic workstation design plays a central role, as many, often physical, activities are repeated over long periods of time (many hours a day, over weeks, months and years).

Using principles of lean production and lean solutions from BeeWaTec, ergonomics, working conditions and preventive health protection can be improved easily and cost-effectively.

In this article we give you 8 tips for ergonomic workstation design - our practice-oriented checklist from many years of experience.

A work table with integrated height adjustment (whether electric or with a crank) is probably the classic in the field of ergonomics.

Height-adjustable workstation systems make it possible to work while standing or sitting, promote the musculature and support the cardiovascular system. The ability to set the optimum working height ensures that both tall and short people can work in a healthy posture. Negative health consequences such as unfavourable sitting postures, tension or back problems can thus be prevented.

Especially in companies where work is done in several shifts (= frequent change of workers), the quick and easy adjustment of the height is an important prerequisite for good ergonomics.

The goal of flexible delivery or provision is to work comfortably within the reach and work space. Things that are outside this zone should be needed less often for a particular activity. The "ideal" zone varies depending on body size. Therefore, flexible solutions are recommended (e.g.: swivelling support arms) that can be easily and quickly adapted to the respective employee.

By linking flow racks or conveyor lines directly at the workstation, materials can be delivered directly to the work process. This eliminates interruptions during assembly activities, which are often caused by fetching materials and corresponding walking distances.

Attached roller tracks and balancers allow tools or implements such as screwdrivers to hang from "the ceiling". This makes them easily accessible and they do not have to be picked up umpteen times a day. In addition, the work surface remains clean, free and clear, which corresponds to an important principle of the 5S method.

Auxiliaries, for example, can be delivered to open fronted storage bins by means of articulated arms or cantilevers. This keeps everything close at hand and at the same time supports the employees' movements.

The provision of information is also part of the ergonomics of a workstation system, as it usually plays a decisive role in the quality of the work result. The well-being of employees also plays an important role here, as informed people are usually more satisfied. Lack of information or unclear work instructions lead to errors in the short or long term.

Information sources such as signal lights, monitors, whiteboards or perforated board systems support work by helping to provide or visualise statuses, processes, work instructions or checklists. In the sense of "self-service", employees can consume the information independently without having to take breaks from work or pick up the phone.

Worker assistance systems such as the ifm mate system go even one step further. By means of camera systems, containers, (gripping) zones and the movements of the employees at the workstation are tracked. These are displayed to the employees themselves on a screen. The individual zones and work steps are given their order by means of colour coding (e.g.: next work step "blue zone"). In this way, the employee knows which movement must be carried out next (e.g.: "Grasp a screw"). Non-executed or incorrect movements / work steps are recognised and reported back immediately.

Especially in the case of frequent changes of activities, or frequent changes of employees at the respective workplace, this type of assistance system can help to carry out the work quickly and without errors.

Flexible, i.e. rotatable or swivelling LED lights that can be individually adjusted according to sitting position and body size, are ideal. Task lights with scalable light output (= dimming function) also ensure optimal lighting conditions because they can be adjusted as needed. They thus provide more light when necessary, but at the same time prevent irritation due to glare.

Optimal light at the workstation has many positive effects:

Poor or insufficient light causes quality deficiencies and creates discomfort and stress. Especially in environments without direct incidence of daylight, optimal lighting is a basic prerequisite for ergonomic work.

But when do we speak of optimal lighting at the workstation? Ergonomic lighting depends first and foremost on the activities to be performed. Based on the DIN EN 12464-1 standard, we recommend the following illuminance levels for industrial workstations:

100 lx means that at a distance of one metre from the luminaire, a luminous flux of 100 lumens hits an area of one square metre.

Noise is an often neglected aspect of ergonomics. However, disturbing noises can mean a high level of strain, cause stress and increase the feeling of discomfort at the workstation. Noise can have negative consequences, especially in activities that require a high degree of concentration.

In production and logistics, the main causes of noise are machine noise, ventilation systems, hydraulic systems or internal transport (e.g. by means of tugger trains).

Possible solutions to combat these causes are for example:

Colours are used to help employees process information and avoid errors.

Common colour information is for example

Another advantage is the fact that the use of colours does not create any language barriers.

Note: When selecting colours, the colour effect / colour psychology plays a decisive role. "Red", for example, signals danger and increases attention. "Blue" or "grey", on the other hand, have a calm and harmonious effect. The processing of colour information usually happens unconsciously, which should also be taken into account in the design.

Physical relief can help to increase the health of employees. They are of great importance for preventive occupational safety and strengthen the focus on value-adding activities.

BeeWaTec provides solutions based on simple mechanical principles - including seesaw, shooter and karakuri solutions.

The goal here is to achieve, with as little energy input as possible

BeeWaTec's lean solutions not only help to relieve the physical strain on employees, but also support the automation of work processes.

In this article we have shown you practical recommendations on what matters when it comes to ergonomics at the workstation and how ergonomic requirements can be implemented.

Ergonomics means that the working environment adapts to the person and not vice versa.

Use our 8 tips as a guide for analysing or designing your workstation systems and for setting up and operating workplaces. Our modular system of pipe racking systems, lift sets, lights and many other accessories form the ideal basis for implementation."

The topic of ergonomics seems relatively complex at first, with many approaches to optimisation. To begin with, consider only one aspect at a time and use the following questions as a starting point together with your colleagues:

In a world where markets are changing rapidly and competition is more intense than ever, organizations are looking for effective methods to remain...

At a time when companies are striving to increase efficiency and cut costs, the concept of lean management has established itself as a highly...

The material flow is an important part of every production and logistics. It describes the physical movement of materials, products and goods through...