use cases for wheel.me

made from the BeeWaTec modular system

Automated transport and efficient processes

Flexible adaptation to any environment

Future-proof and scalable solutions

Rack Transport

Art.No.: 601733

Wheel.me transforms the way rack systems and trolleys are transported by turning them into intelligent, mobile units. Whether adapting existing systems or integrating new designs, the robot functions as a self-moving shelf, seamlessly navigating warehouses and production spaces. While load carriers are manually transferred, the system significantly reduces the need for physical effort, optimizes workflows, and enhances flexibility. This leads to smoother operations, better space utilization, and increased efficiency in dynamic environments.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

Pallet Transport

Art.No.: 601741

Wheel.me redefines pallet transportation by integrating a robust steel frame directly mounted on its wheels, turning it into an intelligent, mobile platform. While load carriers are manually transferred, the system minimizes physical strain, streamlines internal logistics, and enhances workflow efficiency. By enabling smooth and flexible movement of pallets, it optimizes space utilization and supports more agile operations in warehouses and production environments.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

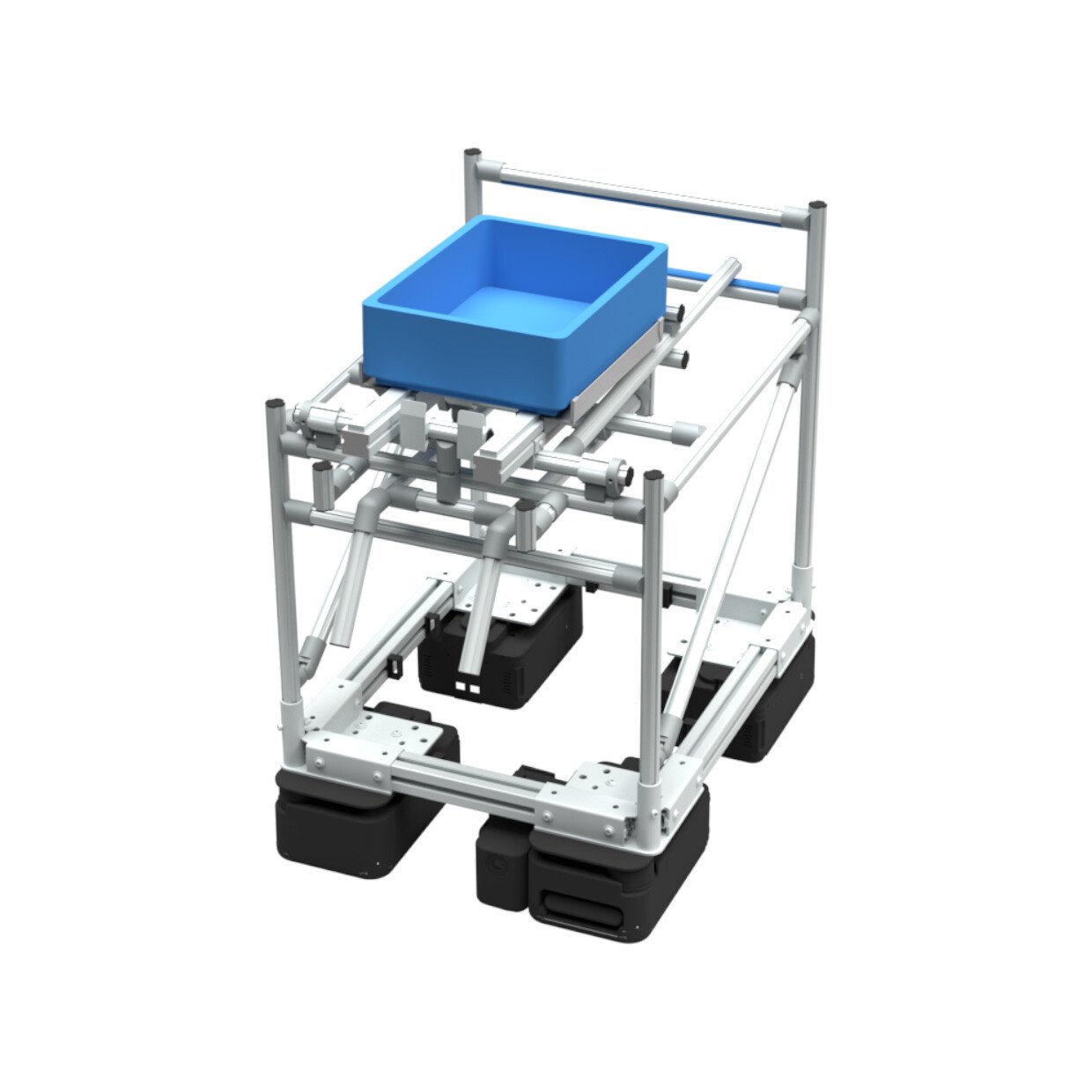

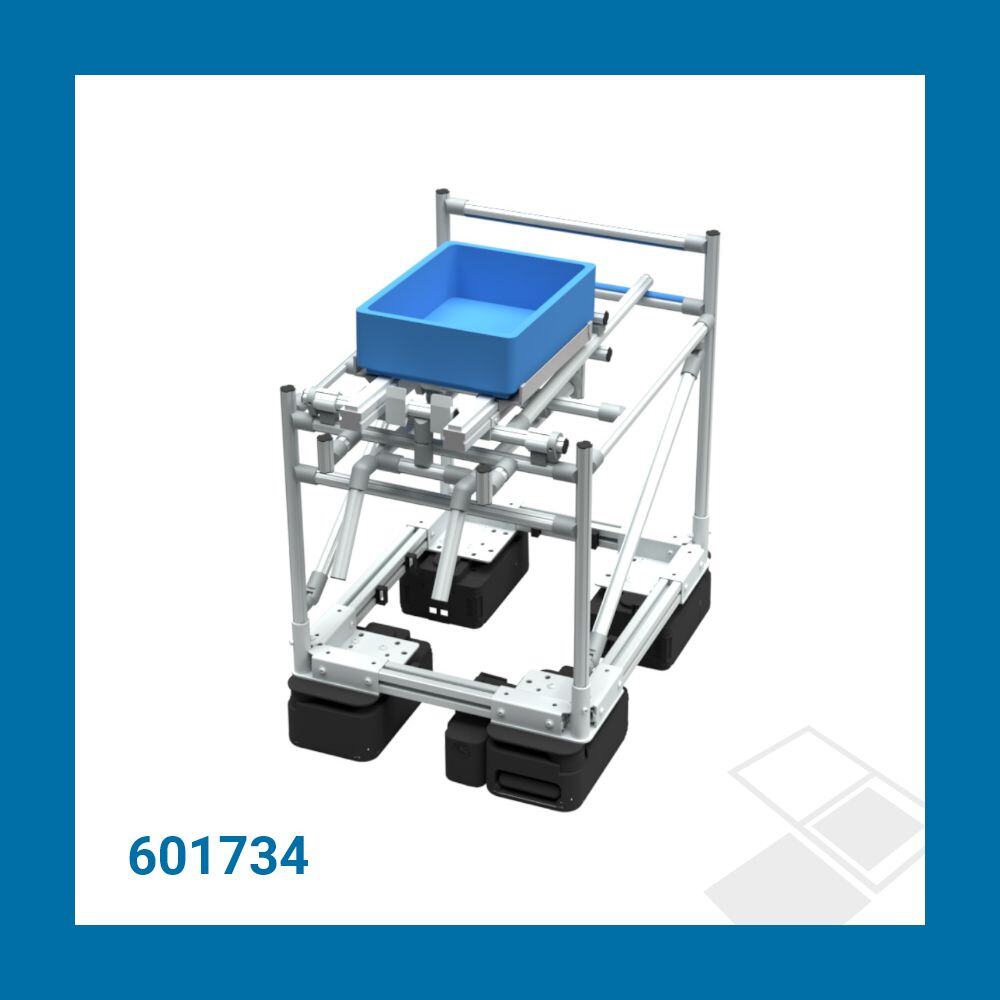

Box Transport No.1

Wheel.me revolutionizes material handling by enabling the fully automated transfer of boxes using a shooter system. With two transfer stations — one as the source and one as the destination, built from a BeeWaTec pipe-racking system — the robot seamlessly takes over material supply without any manual intervention. This increases efficiency, ensures a continuous flow of goods, and optimizes internal logistics, making operations more agile and reducing dependency on manual transport.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

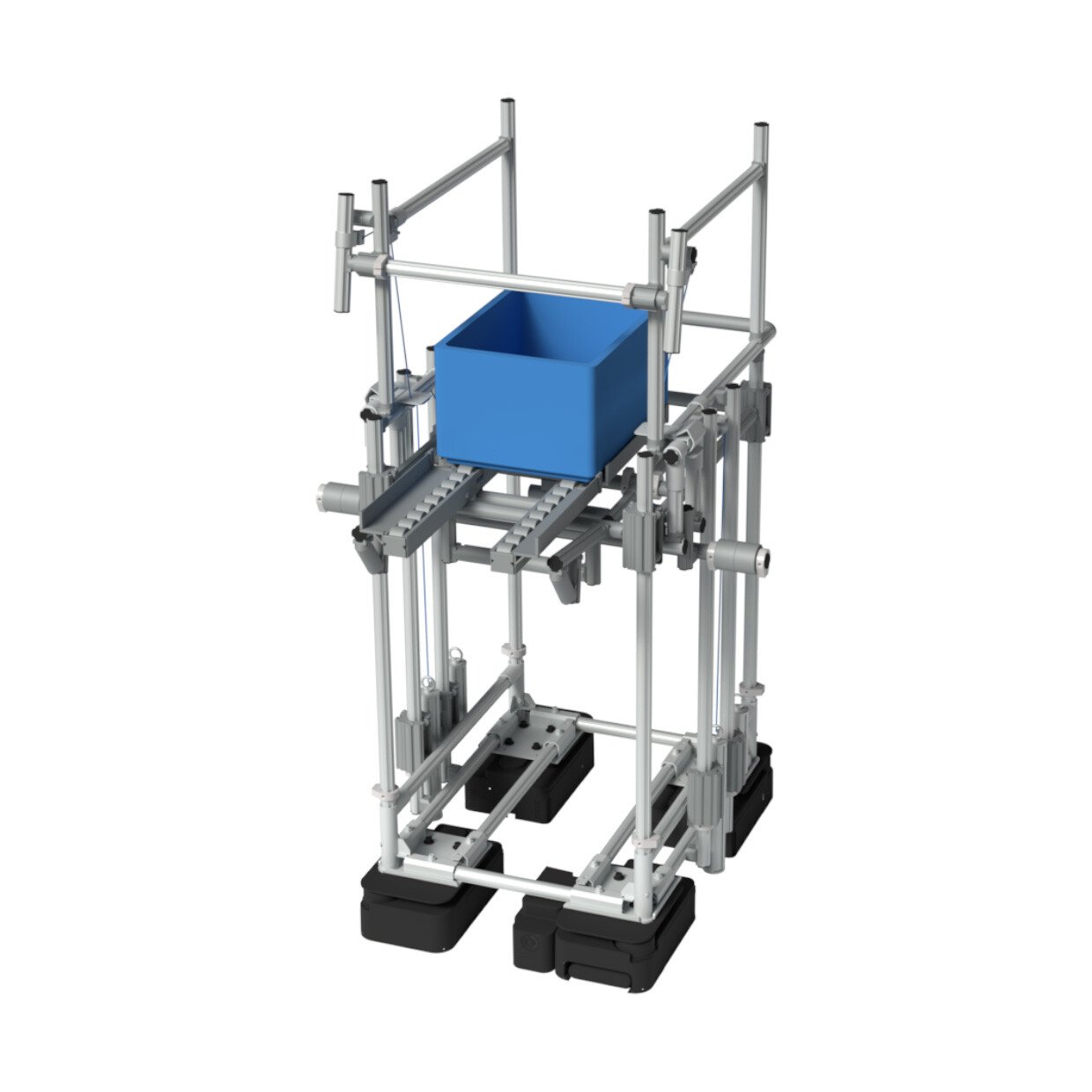

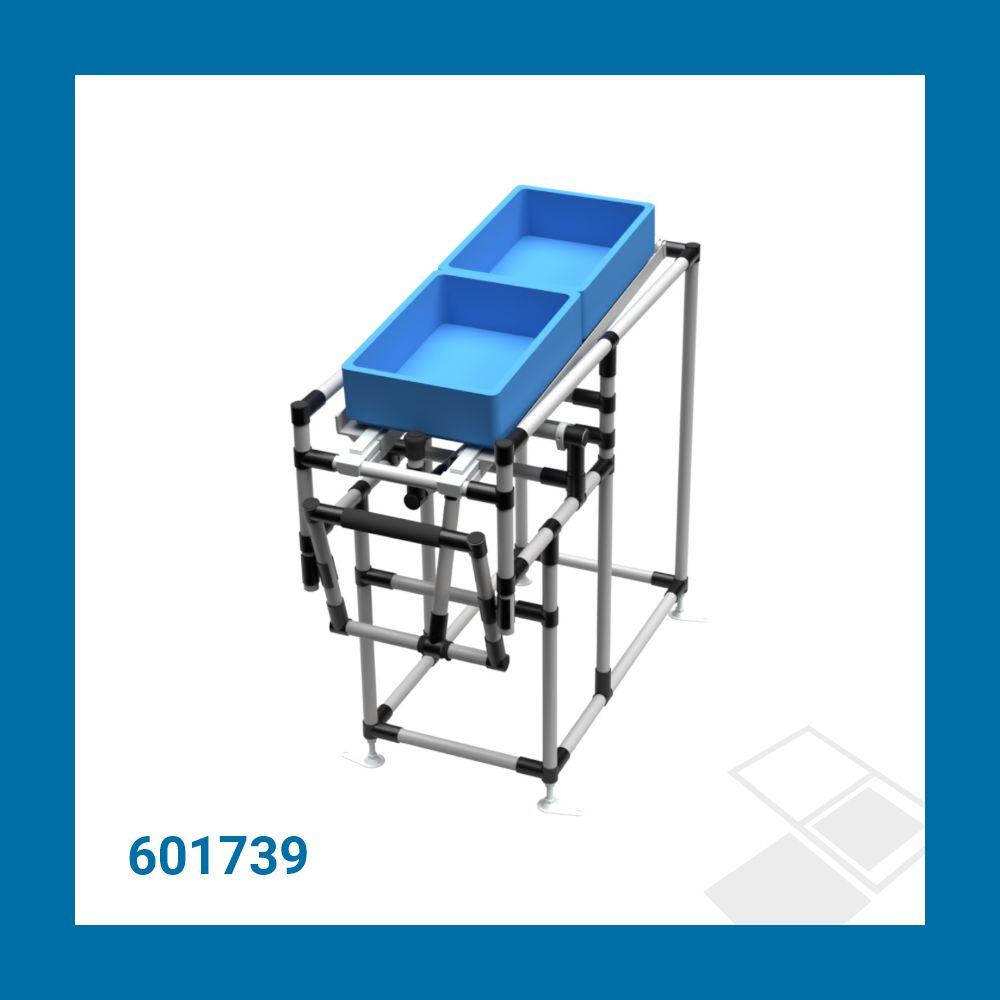

Box Transport No.2

Art.No.: 601738; 601735; 601736; 601737

Wheel.me enables fully automated box transport with a height-adjustable sliding carriage and a tilt mechanism for smooth transfer at pick-up and drop-off stations. By dynamically adapting to different station heights, the system ensures seamless material flow without manual intervention. This enhances flexibility, optimizes logistics efficiency, and reduces the need for additional infrastructure, making internal transport more reliable and autonomous.

💡 Please consider the manufacturer's specifications for wheel.me for each application at the customer's premises. Please contact us if you have any questions about assembly with the pipe racking system.

_Web_01_01.jpg?width=1240&name=Beewatec-3-(37)_Web_01_01.jpg)